Are you ready for OSHA on your job site? Ensuring the safety of your worksite is beneficial not only to employees but to employers as well. A site audit aims to identify safety hazards and develop practices to ensure a safe worksite.

According to the U.S. Bureau of Labor Statistics, 174,100 construction workers were injured in 2020, and 1,008 were fatal. The construction industry is dangerous; however, it does not need to be. By conducting regular site safety audits, you can increase the safety of your worksite.

Reasons to Conduct Regular Safety Audits:

1. Evaluates Effectiveness of Safety Programs: An audit helps everyone learn from mistakes by evaluating how accidents could have been avoided. A safety audit will help strengthen your safety program and make it more effective in future projects.

2. Saves Money and Lives: It is better to find out about a safety risk during a regular audit than after an accident has already happened. It keeps workers safe and keeps costs low.

3. Discover New Safety Hazards: New tools and construction equipment with new hazards are invented every year. A regular audit ensures that you stay in step with the regulations that OSHA sets forth for job site safety.

4. Ensures that Equipment is Safe to Use: Equipment can pose a safety hazard if not maintained correctly. Larger equipment should be checked for damage before use, and all users should receive the proper training for the operation of this equipment.

5. Allows you to Evaluate the Level of Safety Training: If anyone hasn’t attended safety training yet, or perhaps their training has expired, you should schedule up-to-date training sessions as soon as possible.

6. Keeps Everyone Alert: A regular audit of your safety program will ensure that everyone on the job site makes safety a priority and follows safety protocols closely.

7. Increases Productivity: A safe and clean job site allows workers to move around easily and accomplish their tasks more efficiently.

8. Attracts New Clients: Investors are looking for contractors with a reputation for safety as it keeps their costs down and ensures that the job will be completed on time.

9. Verify OSHA Compliance: OSHA has required standards and strict rules for all construction sites. A safety audit ensures that every part of your job site, from equipment to workers, is OSHA compliant.

10. Keeps Everyone Prepared: While audits are meant to cut down on unsafe work practices, accidents will happen. An audit also serves to prepare people for these occasions.

4 Types of OSHA Violations According to OSHA:

1. Willful: A willful violation is defined as a violation in which the employer either knowingly failed to comply with a legal requirement or acted with plain indifference to employee safety. A willful violation comes with a max penalty of $145,027 per violation.

2. Serious: A serious violation exists when the workplace hazard could cause an accident or illness that would most likely result in death or serious physical harm unless the employer did not know or could not have known of the violation. A serious violation comes with a max penalty of $14,502 per violation.

3. Repeated: A federal agency may be cited for a repeated violation if the agency has been cited previously for the same of a substantially similar condition and, for a serious violation, OSHA’s regionwide inspection history for the agency lists a previous OSHA notice issued within the past five years; or, for an other-than-serious violation, the establishment being inspected received a previous OSHA notice issued within the past five years. A repeated violation comes with a max penalty of $145,027 per violation.

4. Other-Than-Serious: A violation that has a direct relationship to job safety and health, but is not serious in nature, is classified as “other-than-serious.” An other-than-serious violation comes with a max penalty of $14,502 per violation.

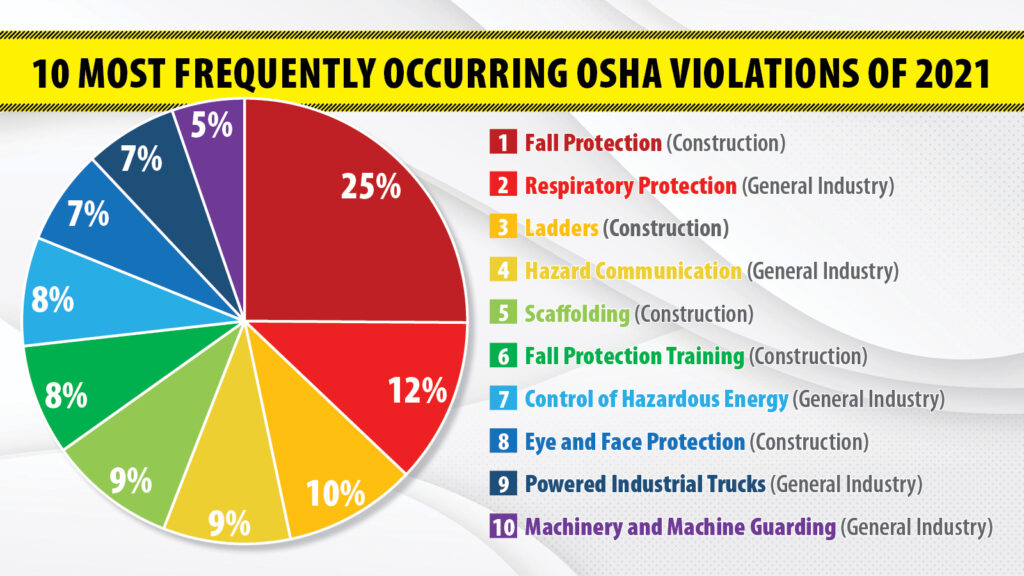

According to OSHA, the most frequently cited violations in 2021 were:

1. Fall Protection (Construction) – 5,295 Violations

2. Respiratory Protection (General Industry) – 2,527 Violations

3. Ladders (Construction) – 2,026 Violations

4. Hazard Communication (General Industry) – 1,948 Violations

5. Scaffolding (Construction) – 1,947 Violations

6. Fall Protection Training (Construction) – 1,698 Violations

7. Control of Hazardous Energy (General Industry) – 1,666 Violations

8. Eye and Face Protection (Construction) – 1,452 Violations

9. Powered Industrial Trucks (General Industry) – 1,420 Violations

10. Machinery and Machine Guarding (General Industry) – 1,113 Violations

OSHA may choose to issue citations and financial penalties to the employer for violating specific OSHA standards or regulations or for violating the “general duty clause” Section 5(A)(I) of the Act. OSHA does not cite or fine employees for violations of their responsibilities. OSHA must generally issue any citations within six months of the occurrence of any violations. Citations are supposed to be mailed to employee representatives no later than one day after the citation is sent to the employer. Citations can also be malted to any employee upon request.

Conducting a site safety audit can help to ensure the safety of your workers and help you to avoid severe OSHA fines. Hiring a third party to conduct inspections can be beneficial as third-party auditors have experience and can provide objective, unbiased opinions that can help empower organizational change. Safety Solutions & Supply offers third-party construction site auditing services. Call us at 866-537-2262 or check our website at www.solutionsinsafety.com to schedule an appointment.