Category Archives: Training

Protect Your Employees From Slips, Trips, and Falls With Our Reliable Fall Protection Remediation Solutions

At Safety Solutions and Supply, we understand the importance of fall protection in the workplace.[...]

Oct

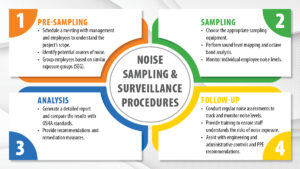

Safeguard Your Employees Hearing With Expert Safety Consulting

October is designated National Protect Your Hearing Month, presenting an excellent opportunity for organizations to[...]

Oct

Managing Heat-Related Illnesses in the Workplace: How to Keep Worker Health Top Priority

As the temperatures rise, so do heat stressors in the workplace, with the potential for[...]

Jun

The Employer’s Critical Role in Ensuring Water Safety

May is National Water Safety Month, a perfect opportunity to focus on water safety and[...]

May

Make the Time to Train

It is essential to ensure your worker's training is up to date not only because[...]

Aug

What are confined spaces in the workplace, how are they dangerous, and how do you keep your employees safe when accessing them?

A confined space is an enclosed area that is not designed for human occupancy but[...]

Feb

Brewing a Safety Culture Within Your Company

Companies that practice a safety-first philosophy can expect fewer employee injuries and greater productivity and[...]

Dec

Mobile Equipment at Surface Mines

According to the United States Department of Labor (USDL), haul trucks and other large surface[...]